If you can't afford to build the Real Thing...

I bought a 1956 John Deere 420C crawler, intending to repair it and play with it around the ranch. However, when the intial parts bill topped $2000 with likely another $1000 to go, it just got to be beyond my means.

I glommed onto this Ertl 1:16 toy on Ebay for a reasonable price, in the condition shown. Replacement tracks are available, the rest of the bits I'll fashion out of brass. As you can see in the first picture, the one I bought had a Model 62 “inside frame” dozer blade on it. I'll reproduce that out of brass as well.

First order of business is to replace the steering clutch/brake handles. One was broken off, the other was incorrect for the machine, so I bent a couple of new ones up out of brass square stock.

I'll paint them to match and use a bit of black heat shrink tubing for the handles. The square hole on the left fender is for the rear light, which was broken as well. I'll fix that and replace it after the major work is done.

The muffler and air cleaner stack were broken off as well, and have been reproduced in brass. The slightly askew muffler wasn't intentional, but is certainly realistic. Most of them wind up getting bent eventually.

It's nice to have the 1:1 scale machine to get measurements and pictures from. These are the pieces for one side of the main mounting frames for the dozer blade.

Here they are assembled. Figuring out a jig to hold the various pieces took a little head scratching.

Here's one mocked up on the crawler frame. Need to brainstorm a way to fix them in place. The original just uses “U” bolts around the track frame mounts. Not possible on the model.

Bent up a bit of flat stock to fit over the diamond-shaped frame members and soldered it to the bottom of the mounting frame. That gave me plenty of contact surface to epoxy the mount to the crawler.

Frame and dozer blade assembly completed. Blade angles manually just like the original. Blade is made from a piece of copper pipe cut in half longitudinally then the curve is "adjusted" in a vise until it looks right. All that remains is to make the hydraulic cylinders and paint it.

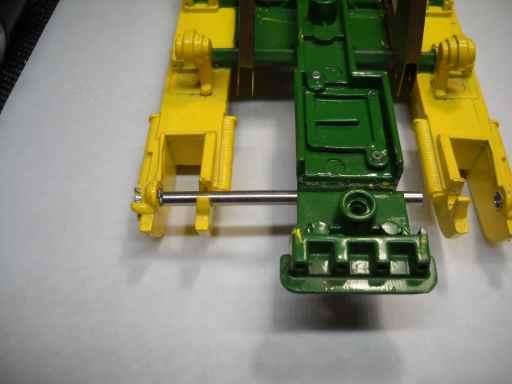

Also needed to modify the front axle. The toy was designed with a full-width axle for strength to resist children playing with it. It fared better than the rest of the dozer (broken air cleaner, muffler, three point hitch and steering levers...) but interferred with the action of the dozer frame.

The solution was to drill through the outside of the "pork chops" or outer bearing on the real machine (the axle just butted up against them on the toy) and then chop the axle off just long enough to fit to the inside of the track frame and epoxy it in place.

Got the cylinders and mounting pins made, installed everything, painted the muffler and put the heat shrink "grips" on the steering levers. I'll order the tracks from Fee Bay and take it back apart and paint it and we'll be done.

Dozer frame and details painted. Still looking for tracks at a reasonable price.

Working on an idea to build my own tracks. Started with an old inner tube that's about 6 inches wide. Didn't see markings to get the industry size.

Then cut a slice out of it 3/4 of an inch wide. Getting the sides parallel takes some fussing. Cut with a new Xacto blade, went reasonably well.

Made the grousers out of some black plastic sheet I had laying around. 3/4 x 3/8 looks about right.

Glued them to the rubber strip with E6000 which is a lot like Shoo Goo. Have some other adhesives to try if that doesn't work out. I'm thinking it will as it should remain somewhat flexible.